Introduction

In the automotive industry, it’s the onset of improvement in everything from vehicle designs to manufacturing and production, while also making the customer experience more personal and transparent. The momentum at which the automotive industry is changing is simply astonishing.

Parallel to all these advancements, one worth mentioning thing is, all of it is fueling a new need for automotive companies to transform digitally. By transforming digitally, businesses can strategize and pivot at the same time. But what exactly does that mean? Well, it means integrating digital technologies into every aspect of a business’ operations. This allows automobile manufacturers to optimize growth opportunities faster than they could before and future proof their operations in new ways.

The Automotive Supply Chain

Did you know, a car is made out of about 30,000 parts, if you count all parts down to the nuts and bolts. Out of this, only 15% is made by the original equipment manufacturer and the rest is supplied by external companies.

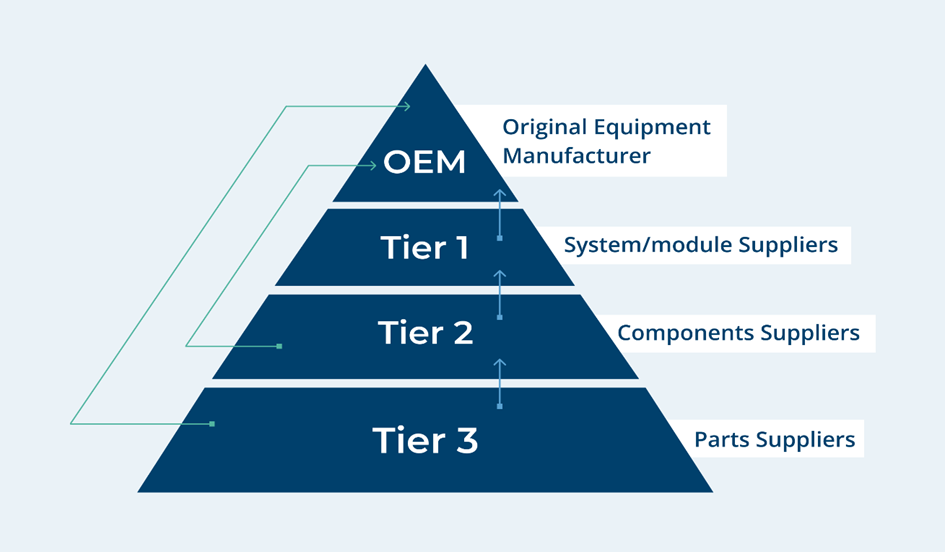

When it comes to the Automotive Industry, the supply chain is segmented into four parts.

- At the top, we have the manufacturers, called OEMs (Original Equipment Manufacturers). They are the big players of the industry who deliver the automobiles that we buy in the marketplaces.

- Second in the line are Tier1 suppliers. They manufacture and supply standardized automobile parts and systems directly to the OEMs. They build their businesses with long term collaborations with these industry giants (OEMs).

- Next come the Tier 2 suppliers who buy raw materials from Tier 3 and use them to produce parts needed by Tier 1suppliers and OEMs.

- Finally, the foundation is formed by the Tier 3 suppliers, who supply raw materials, such as metals and plastic to the OEMs, Tier 1 and Tier 2 suppliers.

The Request for Quotation (RFQs) phase is when the collaboration with other suppliers officially begins. Tier 1, Tier 2 and Tier3 companies are invited to submit detailed technical proposals to become suppliers for one or more vehicle line branded by an OEM or they even trade materials and components amongst themselves. This collaboration between the suppliers and the Tier 1/Tier2/OEMs continues even after closing the contract.

Automobile manufacturers need to empower business units at multiple locations to share production documents with other authorized parties elsewhere. This includes uniting with suppliers and coordinating data across various stages for change of control. Here, routing all documents in one central system which is equipped to send notifications and reminders improves collaboration efforts and is crucial for quick accessing or approving.

5 M’s of the Automotive Industry

In the Automotive Industry, to be the best-in-class, you must leverage the modern technology to automate the “5 M’s” of car manufacturing:

Method– To control the production processes in real time

Measurement– To control the product and process quality in production

Machine– To control the equipment on the production floor

Man– To control the workforce and their activities in production and

Material– To control the integrity and traceability of the materials in production

From request for quotations and managing purchase orders to financial reporting, there are many manual processes that take time away from long-term strategic planning and leave companies vulnerable to human errors. Automotive Automation reduces the risk of human error and ensures consistent and accurate data entry and operational tasks, while freeing your employees to focus on high value tasks. Alongside, digital solutions make everything smoother as no more time is wasted on messy paperwork.

A research on the automotive industry reports that the contracting process generates more than 200,000 yearly documents for a regular automobile manufacturer.

How is Automotive Industry Adapting to Automation?

Several verticals of the automotive industry, be it car manufacturing, supply chain management, dealer agreements, sales or services, are witnessing swift transformation with integrating solutions that help automate digital signatures, P2P and O2C cycles, Accounts Payable automations and more.

- Get away with huge volumes of paperwork:

Intelligent RPA solutions can handle increased volumes of documents, transactions and data without compromising efficiency and ensures that anyone concerned to viewing, signing and approval is instantly notified, thus greatly decreasing the turnaround time.

- End-to-end process automation:

Process automation fully optimizes stock tracking, automates the procurement processes, and enables real-time visibility into inventory levels. It facilitates a single source of data for analyzing to make data-driven decisions in real-time. For instance, procure-to-pay process automation gives quick access to supplier’s documents and effectively manages cashflow.

- Automated document signing:

Integrating digital signature solution for vendor agreements, purchase orders, invoices and more using digital or electronic signatures, allows remote signing from any location, at any time, and via any device.

- Seamlessly integrate Intelligent RPA with existing systems:

Integrating RPA solutions for document management and digitized workflows with other automobile plant systems, such as ERP and CRM systems, is necessary for seamless operations across automobile plants.

Similarly, know how digitalization is changing Logistics Industry in our detailed blog.

Ending Note

Data is one of the most valuable business resources and managing this vast information in the most efficient way has become a real priority for every company.

In the automotive industry, automation can take place both at the horizontal level (suppliers-OEMs-consumer) and at the vertical level (across departments of the organization). It transforms automotive operations by streamlining processes, reducing errors, and improving overall efficiency, thereby reshaping automotive industry standards and customer expectations.

Curious to know how Symtrax will help your enterprise transform digitally?

Connect with us here for a free demo!